Lean Clean Technology

Lean Clean GmbH Sondermaschinenbau is a worldwide supplying company for Cleaning systems and punching and bending machines

who we are

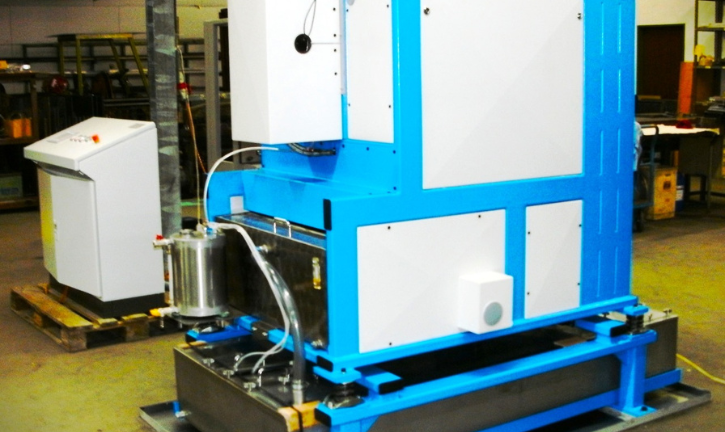

Lean Clean Technology has established itself as a global pioneer in the design, manufacture, and supply of advanced Inline Cleaning Systems and stamping-bending machines. Our journey began long before our official founding in 1993, driven by the innovative vision of our Founder and Managing Director, Mr. Gregor Schulze-Eyssing. With a deep understanding of the challenges faced by production industries, Mr. Schulze-Eyssing foresaw the potential for a transformative solution that would enhance efficiency, reduce waste, and support sustainable practices.

At the heart of his groundbreaking concept was the integration of cleaning processes directly into the production line. He envisioned a system capable of cleaning screws, nuts, and stamped and pressed parts during production while simultaneously recovering and reusing valuable production oil. This innovative approach not only streamlined operations but also delivered measurable cost savings, reduced environmental impact, and improved the overall quality of the final products.

Since our inception, Lean Clean Technology has brought this visionary idea to life with our state-of-the-art automatic Inline Cleaning Systems. These systems have become synonymous with precision, reliability, and sustainability, enabling businesses across a wide range of industries to optimize their processes and achieve new benchmarks of performance.

Our Products

TS 50

T 50

WS 30

WT 50

SF 500-2

SF 500

Why Lean Clean Technology

Lean Clean GmbH is one of the most innovative partners in the field of Inline Cleaning at the Mass production of parts in connection with the requirements set by the industry. The continuous development of ever better solutions forms the basis for the excellent market position of Lean Clean GmbH. The aim of Lean Clean GmbH is to provide the most process-reliable and highly developed Inline Cleaning systems and their peripheral components (conveyor technology, bath maintenance,filter technology) that make it possible to add value to the company’s growth. Furthermore, Lean Clean GmbH guarantees high quality and constant innovation and consistent customer orientation.

Mr Gregor Schulze Eyssing

CEO/Founder

Dr Xavier Suhan Rasquinha

INDIA HEAD

Contact

Call Now

8904474264

www.leancleantechnology.com

Location

India,Germany